Jiaxing Willing Lamiglass Material GmbH (W.M.C) has rich experiences of 8 years to produce EVA film for laminated glass both for industrial applications of exterior and interior. The factory has 5,200 square meters and own two EVA automatic production line, the product with superior quality for glass industry and processing.

We produced EVA film for applications of glass laminating processing and solar panel, mainly for architectural laminated glass which has more excellent performances like safety, Security, acoustic insulation, energy saving, chromatics and creations. Aesthetics can be fully applied in field of architecture.

EEthylene vinyl acetate (also known as EVA) is the copolymer of ethylene and vinyl acetate. The weight percent vinyl acetate usually varies from 10% to 40%, with the remainder being ethylene.

It is a polymer that approaches elastomeric materials in softness and flexibility, yet can be processed like otherthermoplastics. The material has good clarity and gloss,

low-temperature toughness, stress-crack resistance, hot-meltadhesive waterproof properties, and resistance to UV radiation. EVA has a distinctive "vinegar" odor and is competitive with rubber and vinyl products in many electrical applications.

WMC GLASS is at the forefront of continuous innovations in the development and manufacture of all processes productive thanks to technology that gives us the optimization of the resources of our customers. Working for companies that give a absolute priority to R & D and are always interested in new technologies production.

WMC GLASS has devised to create infinite kinds EVA film for different applications such as construction projects,EVA film laminated glass can be installed interior and exterior places that its laminated glass own high transparency and brightness; Colored EVA film almost used for interior decoration of window, kitchen, furniture, entertainment venues, also colored transparent/translucent and opaque EVA film for private space like office partition, meeting room, hallway and shower room; for special lamination with other material insertions can choose our functional EVA film.

High quality EVA interlayer is processing in laminating glass with high transmittance and durable adhesion with different laminates. Different application request its temperature depends on insertion material and specific operation. Generally speaking Willing company can provide suitable EVA film with different melting points can be bond with different material in laminating processing. Universal EVA film transmittance can reached over than 90% with clear float glass after laminating, if you need a higher rate of transmittance please use Willing company high/Ultra transparency EVA film which can be up to 92% transmittance rate; Willing®EVA Film has good bonding with many kinds material not only glass but also Acrylic, PET, PETG, PVC, PC, Fabrics, Silk, metal,plywood, solar panel and specimens, are undergoing change and deformation at high temperatures, Willing ®EVA film allows working at low temperatures such so that the laminated glass inserts did not suffer any alteration. Deco-Laminated glass with Willing®EVA film will be your private custom interior items, and its an really exclusive artwork.

Today, glass decoration has become an integral part of interior decoration, Willing®EVA film owns superior quality with glass as perfect interpretation of its excellent safety and color. If glass was shattered by external accidents, broken glass like a spiderweb to be bonded on EVA film that can avoid injury. The color film is unparalleled, color scheme gives the aesthetic visual experience.Willing®EVA film can be used for architectural laminated glass including exterior, interior, decorative safety glass applications.

| ITEMS | UNIT | Transparency | Colored |

|---|---|---|---|

| Thickness | mm | ± 5% ± 5% | |

| Width | mm | + 3~5% | |

| Length/roll | m | 100/50 | |

| Color | Universal & High transparency | All Colors | |

| Glass adhesion at 80°C | N/cm | 18 | 35 |

| Glass adhesion at 120~135°C | N/cm | 18 | 35 |

| PET adhesion | N/cm | 35 | 14 |

| Temperature adhesion | ºC | 100100 | |

| Temperature fluidity | ºC | 8080 | |

| Light Transparence | % | 80°C= 87.5% 120-140°C = 91.6 % |

|

| UV Flitration | % | ≥98 | |

| Haze | % | 0.6 | |

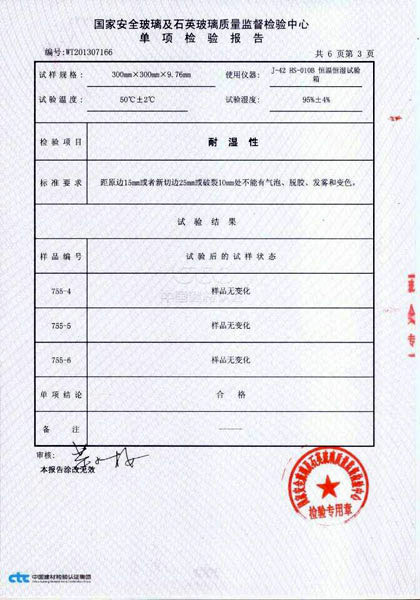

| Humidity Resistance | 50°C,95%RH,400hrs | Qualified | |

| Water Absorption 23ºC, 24 hours | % | 0.1 | |

| Breaking Tenacity | kg/cm2 | 290 | |

| Tensile elongation | % | 2340 | |

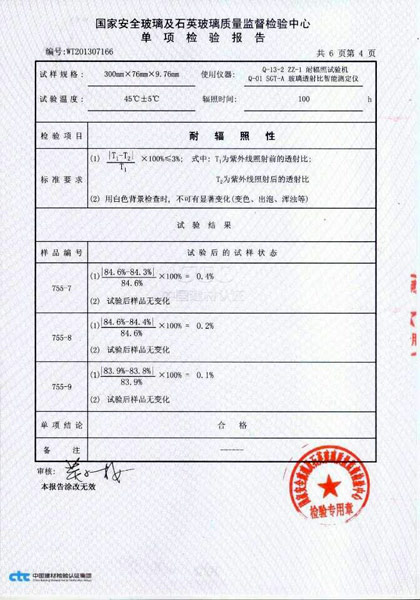

| Anti aging- Standard UV radiation test | Outdoor 120 days | Qualified | |

| Anti aging- UV radiation test for 200 hours | 200hr △YI | Qualified | |

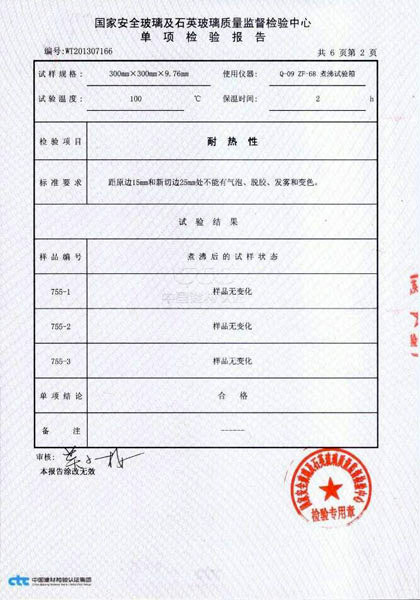

| Boiling test | 100 º C, 2 hours | Qualified | |

| Freezing resistance | -40 ºc, 2 hours | Qualified | |

| Resistance to 100°C water | 3 months | Qualified | |

| Resistance to humidity | 50ºc, 95% RH, 2 weeks | Qualified | |

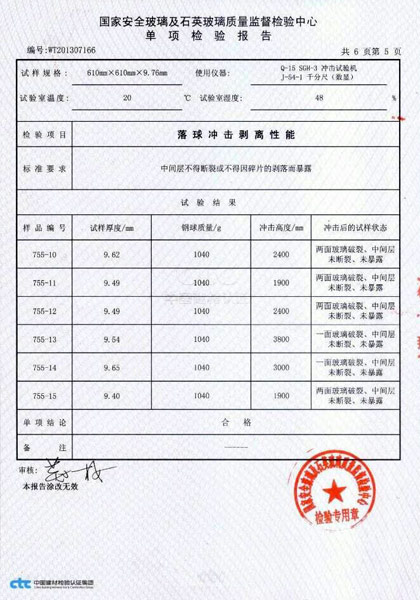

| Impact -Ball falling 4.11 kgs to 3/6/9 height 3 impact | Qualified | ||

| Pendulum test | Qualified | ||

| Deviation Color Tolerance | % | - | -10 |

| LABORATORY DATA | 80ºC 120min 130ºC 50min |

|---|---|

| Proof of artificial UV aging temperature within 50ºC |

Temperature 50ºC |

| Humidity 65% | |

| Radio 1w/m2 | |

| Time 2500 hours | |

| Result=Qualified | |

| Test resistance to high temperature and low temperature cycle |

Temperature 80ºC 40ºC |

| Cycle time 4 hours | |

| Cycle number 50 times | |

| Result=Qualified | |

| Constant temperatur and humidity aging test |

Temperature 50ºC |

| Humidity 97% | |

| Time 400 hrs | |

| Result=Qualified |

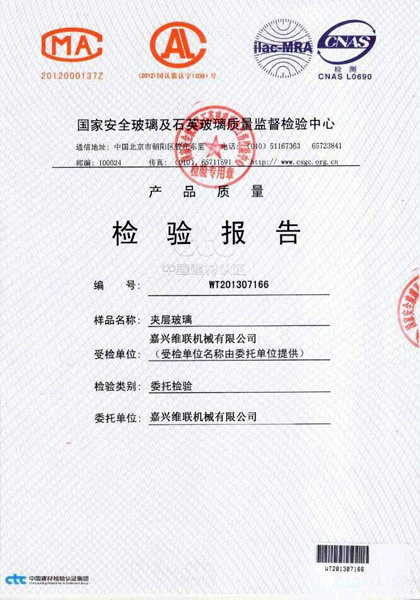

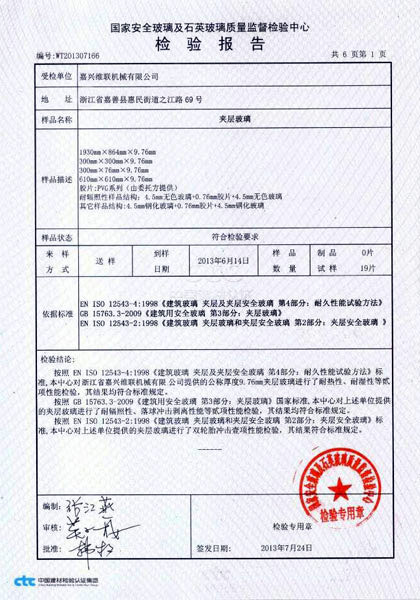

***We are confirming above certificates compliance required by the Chinese plastics standard, architectural glass glazing and European Community***