The moisture of Willing®PVB interlayer will directly affect many key performances of laminated glass, not only bond strength, impact resistance, but also influences on the and Stacking bonding and preheating processing, so PVB interlayer moisture content is a pivotal factor in glass laminating process.

For selected well of glass and PVB interlayer film,PVB interlayer moisture content directly affects adhesiveness between glass and PVB film. In fact, adhesion will be effected bond strength and impact resistance of laminated glass units. Adhesion strength and impact resistance which two parameters related to performances of laminated safety glass ,that’s why should control PVB film moisture content strictly, to make sure adhesive force and impact resistance are controlled in safety standards range. To get perfect laminated glass, must control PVB film moisture 0.3%~0.5% in any condition.

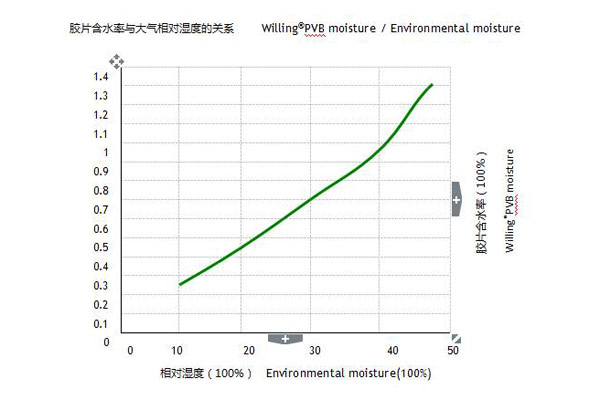

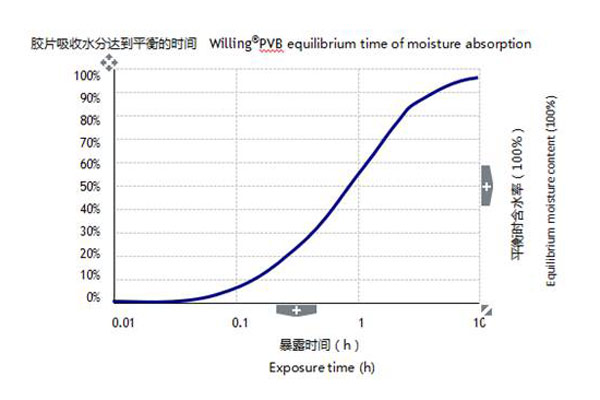

According to the chemical formula of Polyvinyl Butyral shows, PVB film is a hydrocarbon and an absorbent material. Its moisture changes by environmental humidity and time if PVB film exposed in the air, when absorbent material is exposed to a certain temperature and humidity environment, moisture will be transferred from each other between the absorbent material and the air, until reached moisture equilibrium between absorbent material and environment, so may adjust environmental moisture can be changed PVB film moisture in storage.

According to moisture balance, final moisture can be determined under the relative humidity. In order to ensure PVB moisture content, new opened PVB film or roll must be stored at cleaning room where humidity around 23%~28%, temperature 20 ~ 25 ℃ over than 24 hours, PVB film moisture content reach standard then laminating.

At present, most of the laminated glass used in construction is made of resin type PVB interlayer film. Now let’s study the techniques for laminating process with PVB interlayer.

PVB film can be opened and cut by hand on workbench, with methods of mechanical and automatic cutting machine to cut PVB film which are uniform and accurate that effectively utilized PVB interlayer. PVB interlayer edge size need a little bit longer than glass dimensions, because PVB film will shrink while laminating process with high heating, be sure there is no waste PVB or not enough PVB after laminating if shrinkage, from experiences we would like to obligate 5mm for any emergence. If make multilayered interlayer for laminated glass, PVB interlayer should be cut in the same direction accordingly for ensure product quality.

Considering of stable quality of PVB interlayer, well cut PVB film be stored at humidity 23~28%, temperature 20-25℃% over 24 hours to laminate process. According to the relation between relative humidity and moisture content of PVB interlayer, see diagram, if moisture content is 0.5%, relative humidity 21.5% - 24.5%, suitable controlling of humidity can be avoided delamination of PVB interlayer and glass.

In period of storage, in case of air or dust polluted PVB film, can be covered by interleaf film (PE film). PE interleaf film itself didn’t have adhesive so PVB interlayer can not stick together with interleaf film. However, influence PVB interlayer bonding properties, Stack height is generally 10 ~ 15cm, not too higher. If used a part of PVB film but not finish all from 1 roll, should repacked as well and die air so that keep balance PVB film with good adhesion, if stored place at 23%~28%RH and 20~25℃, the balance PVB film no need to replace other package.

Due to PVB film moisture have big affects in quality of laminated glass processing, to get best performances of PVB film must be precisely controlled moisture in producing PVB film and measured moisture content in processing. Although PVB interlayer moisture content can be controlled by environmental conditions and exposure time, ensure moisture content of the PVB interlayer in production and make record all time, it is necessary to test PVB interlayer moisture periodically, make sure the stock quality are fine. WMC GLASS have the automatic PVB film production line, so the infrared spectrum analyzer and Pachymeter can measure PVB film thickness and moisture all time, according to record in production, technical engineer adjusts technologies in time and make sure have uniform thickness, standard moisture PVB interlayers.

The temperature and cleanliness are very important factors to produce high quality laminated glasses. If have impurities on glass sheet or PVB film that will not only affect appearance of the laminated glass but also broken their adhesion properties, impurities on glass surface causes delamination, unglued and low bond strength. Probably Spot-liked delamination and low bond strength be caused by uncleanly glass sheets or PVB interlayer.

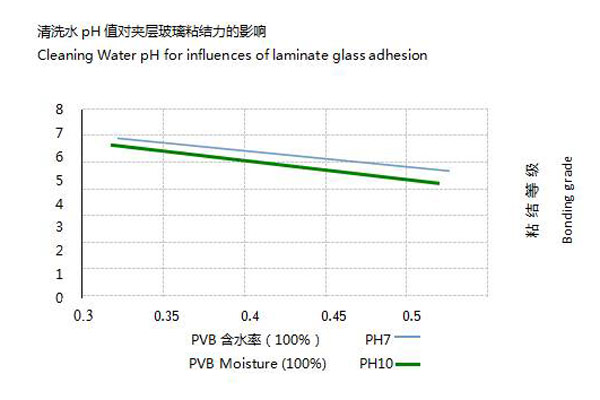

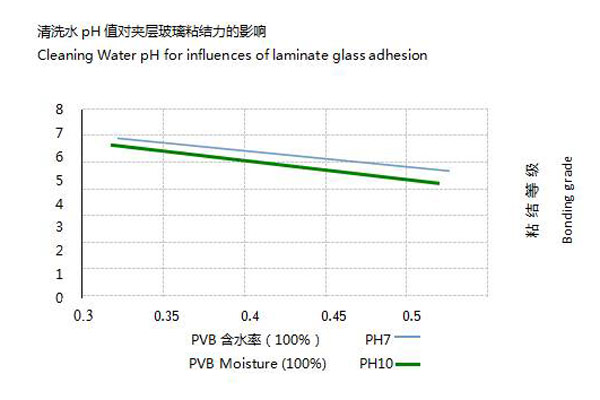

Before laminating, washing and cleaning glass purpose is to remove residual contaminants. The quality of washing water has a great influence on the adhesion between glass and PVB interlayer, because water conductivity has influence bond force on laminated glass. If there has drop of water or residual water on glass sheet after washing and cleaning, water itself can be considered as contaminants.

Water quality will affect bonding properties of glass sheets and PVB interlayer, such as water hardness, metallic ions, PH value, as shown in Figure below.

Water hardness, metallic ions, PH value which all elements was changed by water resource, different area have their quality of water, better to use deionized water or pure water to washing glass. Washing machine consisted of washing and drying sections. First wash is best to use 40-60 ℃ common water plus overflowed water from back, in order to remove some spots, like oil stains, perspiration or fingerprints etc; Second wash is same as first wash in order to strengthen and ensure cleaning effect; Ca +, Mg + will remain on glass after drying, this will caused lower bond strength and safety performance, so generally use ion systems or reverse osmosis system to remove salinity. Water conductivity value or hardness value increase means salinity is higher, so water for washing laminated glass should use pure water which must have lower saly, and resistivity > 100MΩ or conductivity < 10μs. Drying sections used air-knife or nozzle to blow off. Temperature and transfer speed of glass affects water evaporation. When water is blown away while salinity along with, so that improve adhesion.

In production of laminating processing, bent glass or tempered glass can not use washing machine to wash glass, it need to clean by hand to clear impurities away from glass surface, in order to ensure quality and performances of laminated glass. When laminating must consider suitable temperature, not too low nor too high; to ensure that there has stickiness between glass and PVB interlayer, which stickiness makes PVB interlayer to move freely in order to maintain its correct position. Refer to experience value of glass surface temperature between 21 ~ 35 ℃, too low temperature will move PVB interlayer and appear folds; too high temperature will cause shrinkage, folding, but also cause earlier edge sealing, that is one reason to result in air bubbles, if temperature is too high will result in hard to change position of PVB film.

laminating operation room is a place where can store upcoming PVB interlayer and can lay PVB interlayer on the glass. The laminating operation room needs strict requirements; it should reach one million grade pure requirements, in order to ensure humidity and temperature in operation room, should be equipped with air condition and dehumidifier to keep constant temperature and humidity requirements, in laminating should pay special attention to PVB interlayer storage and clean environment, hair, clothing fabric, together, if the control is lax, there will be hair from the operator, clothing fabric, dust and contamination from operators, those details directly influence on performance and quality of laminated glass, so for producing high quality laminated glass the laminating operation room

should do the followings:

The washed and dried laminated glass entered operation room have to be stored in suitable environment of clean, constant temperature and humidity room, in order to improve production efficiency and reduce costs, can be made required size of PVB interlayer for further using, this way can short time to laminating, as soon as glass sheet is out then can put PVB film on glass to laminating immediately. Glass is transmitted through transfer station to the right place, suction cup will suck up one lite until PVB interlayer is already putted on below another lite correctly; transfer bench has liftable caster even if glass isn’t in appropriate position that can also be adjusted by caster. How to put and trim PVB film as well as important in laminating working room.

Improper putting operation will cause defects of laminated glass. The main defects shows wrinkle, pattern dislocation and shrinkable. If happens above defects that have serious quality problems in subsequent delamination, low bonding and during processing in autoclave and resulting in final product quality of laminated glass, it must be very careful to put film on glass flat without any impurity in it.

The other important processing is trimming PVB film before enter to roll-heating section or vacuum processing, When trimming, PVB interlayer can not be extended overly stretch otherwise it will lead to reduction of its thickness, resulting in PVB film returns back rapidly and air be blow into laminated glass as air bubbles when is rolling processing, try to trim PVB film edge and close to glass, according to experience value is about 5mm.

After PVB interlayer was laminated by two glass sheets which are ready for deairing and laminating, the processing of deairing and laminating stages are most important in quality and performance of laminated glass, it’s also important part of finished laminated glass quality and yields.

According to process requirements, laminator combines heating furnaces and pressing rollers, heating furnaces may be electric heating, infrared heating or hot air heating, according to glass and PVB interlayer absorbing performance, infrared heating is ideal, either chinese equipment or imported equipment are generally chosen infrared heating. Pressing roller is generally cylindrical, it can be reached purposes through heating and rolling as followings:

Only expel air is not enough, if didn’t have a certain cohesion, probably happen delamination, there must be a certain temperature to make the glass bonded together with a PVB interlayer, and make sure gets good sealed, so like this the air will not be returned. If has worse edge sealing the air will invade laminated glass to makes air bubbles in edge and delamination. The temperature can not be too high, can not seal edge too earlier before deairing, once edge was sealed, the air can not be expelled from laminated glass anymore.  If residual air is more than solubility of air in PVB interlayer, it will happen air bubbles after produced in final product. For above reasons, in procedure of roller pressing and laminating, temperature, speed, pressure and other parameters must be strictly controlled. Picture shows a schematic diagram of roller pressing.

If residual air is more than solubility of air in PVB interlayer, it will happen air bubbles after produced in final product. For above reasons, in procedure of roller pressing and laminating, temperature, speed, pressure and other parameters must be strictly controlled. Picture shows a schematic diagram of roller pressing.

Because it involves the pressure, temperature, speed and other parameters, to accurately determine roller pressing, expelling , bonding and edge sealing conditions that have certain degree of difficulty. The key technical processing is roller pressing and deair in laminating that achieved without bubbles and without edge defects, the most key technics related with roller pressing force, temperature and line speed of glass and PVB interlayer film, also other factors effect of deair performance, these factors are not easily controlled including flow-ability of PVB interlayer, moisture, roughness and alignment of glass sheet, colors, varieties, specifications and so on. Two glass dislocation will increase air content and in difficult processing of roller pressing. Different color, varieties,specifications of glass will change heating absorption in furnaces, thereby changing temperature of glass surface, so have to sum up experiences of different types of glass in order to provide accurate reference data for future production.

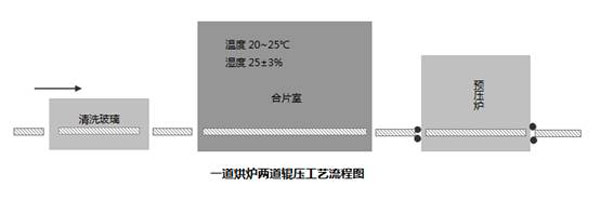

This processing is only for common flat laminated glass production, shown as picture, in environmental temperature, first should be roll-pressed for laminated glass, then heating and following rolling pass, this kind machine for deairing and edge sealing are done through second sets of rolling. In order to achieve success in deairing and sealing under first rolling-pass, glass surface temperature should be controlled as well, recommend glass surface temperature within 64 ~ 71 ℃ generally when before enter to second roller pressing.

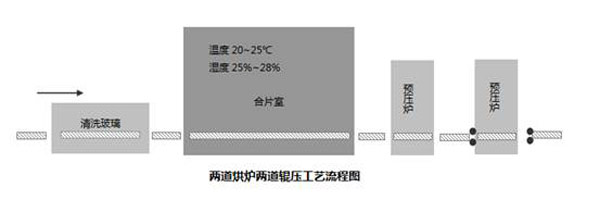

This process is used for quantity production line in laminated glass, most manufacturers are using this production line, Picture shows two furnaces with two sets of roller pressings section, both laminators purpose are deairing and edge sealing independently, first laminator is mainly deairing, second laminator is different with first laminator in temperature only. First lamintor will heat glass surface up to 35 ℃, then trough first set of rolling to deair, pressure 0.25 ~ 0.5Mpa, roller gap is 10% less than total glasses thickness; To maximize deairing, first furnace temperature is very important, if temperature is too high, glass surface temperature is higher after pressing, the air didn’t exhaust before edge sealing, air stay inside and hard to die; if temperature is too low, the air in laminated glass which can not be exhausted will exist bubbles in further process, so it is necessary to strictly control the temperature of first laminator. When enter to second laminator to process edge sealing, its temperature better to keep 70 ± 5℃ and pressure 0.55 ~ 0.75Mpa, roller gap is 15-20% less than total glasses thickness, roll degassing process reference parameters are shown in table

| Roller pressing | Glass Surface temperature(℃) | Roller gap | Roller pressing force (MPa) |

|---|---|---|---|

| First laminator | 30~40 | 90% of total glass thickness | 0.25~0.5 |

| Second laminato | 65~75 | 80% of total glass thickness | 0.5~0.75 |

Only for references, perfect temperature depends on type of laminated glass, size, thickness, roller pressing force, and line speed.

Three criteria to judge deair and edge sealing in good are appearance after pre-pressing, boiling and finish laminated glass appearance; last two is important but found after laminator, so that caused batch of product quality problems. Try to avoid loss should be checked in processing of deair and pressing and adjust parameters in time if find any defects. Therefore, laminated glass processing required people who has more experiences to perform, visual inspection should include following aspects:

(1) Deairing

From out from first furnace (before rolling), laminated glass should be uniform color and fuzzy, any clear areas possibly is hot spots (tape) or in contact with heat transfer station, These may have been completely sealed, so dressing materials on insulating heat transport table, it can improve temperature is even of laminated glass.

When laminated glass through first roller, may see the air waves discharged from edge slowly, then glass trailing edge must be separated, it help bubbles escape. When laminated glass is out from first laminator, glass is almost clear but at edge is clear, If saw dark or fuzzy bubbles in, it indicates that no air was out yet, especially at afterbody. So need to pressing continuously in order to make even transparent laminated glass.

(2) Edge Sealing

Laminated glass passed two lamintors will become more transparent and have clear edge, around 5 ~ 25mm completely transparent and extends to inside of laminated glass. If wasn’t sealed which means air into laminated glass during processing of autoclave.In general, higher temperature, stronger pressing force or slow speed can get a better edge sealing effects.

In processing of laminating, possible will happen fuzzy region, if so, it can not be disappeared neither, because air once into laminated glass and hard to escape even through high temperature and pressure processing, it usually uses method of vacuum deairing to remedy it.

(1) The use of vacuum degassing and requirements

Vacuum degassing process is to solve bending laminated glass, curved tempered laminated glass, multiple laminated glass, this processing is a effective method to solve imperfected edge sealing after rolling. For automobile windshield that is kind of bending laminated glass, mainly use to air circulation.

The production condition of vacuum deairing is almost same as rolling. Deair effects is considering as air bubbles in laminated glass after high temperature and pressure, judge to good laminated glass should following tests of boiling and heating processing, after laminated glass was out, then make a decision; Because of pre-pressing effects is correlated with quality of finish product, so check or control daily production, pre-pressing appearance is known after deairing, if find appearance defects immediately to correct action in processing and can be take to correspond.

Since a amount of residual air can change transparency, it is usually based on degree of glass and edge transparency to and edge judge quality of deairing processing. Between glass and PVB interlayer has more air, while laminated glass appearance is more foggy after initial pressing. Visually speaking, use of vacuum deairing method is more transparent than rolling.

Vacuum deairing production process is mainly used in special laminated glass which is a combination of size and form can not be used the way of roller to deairing sometimes. Normally vacuum deairing bag will be installed in close of production line, and connecting with vacuum source to degassing at room temperature. The most important is to ensure that vacuum pipe is not deformed when vacuum degassing. After vacuuming, vacuum port should be closed and vacuum bag separated from vacuum pump. Cumulative laminated glass should be put on autoclave cart is ready into autoclave under high temperature and strong pressure.

(2) (2) Key processing factors of vacuum degassing

Key processing factors of vacuum degassing are glass sheet and PVB film temperature, degree of vacuum, vacuum time, and maximum temperature of glass sheets.

(a) Starting temperatureStarting temperature

When start to laminating, PVB film is take from Laminating glass room where has lower temperature while PVB film surface has less changes of roughness, it can be deair as much as possible; to prevent dislocation between glass sheets and PVB interlayer in laminating, so it need to adhesive between glass sheet and PVB film, that’s why temperature must be appropriate to balance these needs. Laminated glass surface temperature is room temperature, when meet thicker lites or mutilayer lites, these laminated glass are relatively heavy and have strong press to PVB interlayer film, it is recommended use lower temperature films and operation room temperature should keep 20 ~ 25 ℃. Vacuum degassing usually operates at room temperature.

(b) Degree of vacuum

Vacuum degree guaranteed all the air be exhaust, minimum requirements of vacuum is -0.08MPa, it be able to have an ideal result, piston and rotary vane vacuum pump can be achieved.

(c) Vacuum time

The most important is to ensure that have enough time to deair completely, vacuum pressure should be stable. Install vacuum device at vacuum connector and another end of laminated glass that can show degassing effect. 10 ~ 30min vacuum pumping is enough, but vacuum time is relative with glass design, shape, equipment, and stability of vacuum, the effect of vacuum is adjusted according to actual production. If still deairing in autoclave, the vacuum time is according to autoclave working time, the time is usually longer than heat vacuum time. If vacuum processing before into autoclave, the maximum heating temperature is maintained at 95 ~ 110 ℃. If cooling rate is slow, should use lower temperatures,;on the contrary, high cooling rate can be used a higher temperature. As total thickness of laminated glass exceeds 18mm, should be maintained at the highest temperature of 15min or more. If still been heat vacuum processing in autoclave, the maximum temperature of heat vacuum should meet autoclave parameters, the maximum temperature of autoclave can reach upto 140 ℃.

(1) The purpose of autoclave processing

Autoclave processing is last step of Laminated glass also is a very important stage,it given a suitable temperature, pressure and time, through this processing have following effects:

Through heating, pressurization, suitable time, laminated glass have good transparency and excellent safety performances. After deairing, roller pressing, or after vacuum, it should be sent directly to autoclave as soon as possible, if delay too long time then into autoclave to process, PVB film didn’t have fluidity to course PVB film can not bond with glass sheet as well, because of roller pressing required temperature not too high. The laminated glass not promptly into autoclave after roller-pressing, it may cause delamiation.

Laminated glass should load in autoclave cart, and spaced apart from each laminated glass sheet. It ensures that both sides of each laminated glass sheet be able to get uniform force in autoclave processing. Sometimes In order to increase adhesion between glass sheets and PVB interlayer to bonded together firmly, it used clip to fix at edge of laminated glass This way willl make PVB film get thinner and avoid delamination.

(2) Theory of autoclave processing

As amorphous polymer of PVB interlayer, it is the viscoelastic materials at low temperature, while at high temperatures it has a flow-ability properties. This material has a certain temperature range, also with elastic memory properties, there is a kind strength to stop its elastic deformation; and viscous resistance is desirable to move past each other chain polymer molecules permanently to maintain this deformation. One object of laminated glass to give heat pressing treatment and temperature, so that permanently maintain PVB interlayer film has flow-ability, and with good adhesion between glass surface and PVB film.

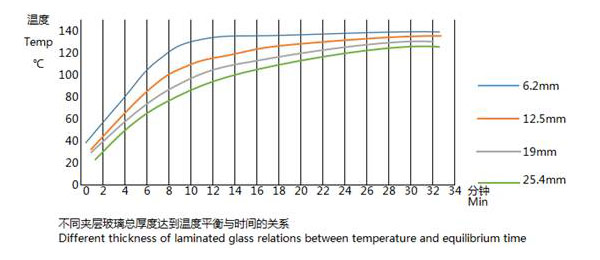

In autoclave, the heat spread to laminated glass by flowed air and heat radiation, transmitted through glass to PVB interlayer; conduction time depends on PVB film which required time of viscous flow. Reached equilibration temperature of PVB film required time that depends on total thickness of laminated glass as shown in picture, the thicker laminated glass need longer time to reach temperature equilibrium.

(3) Heat-pressing processing in autoclave

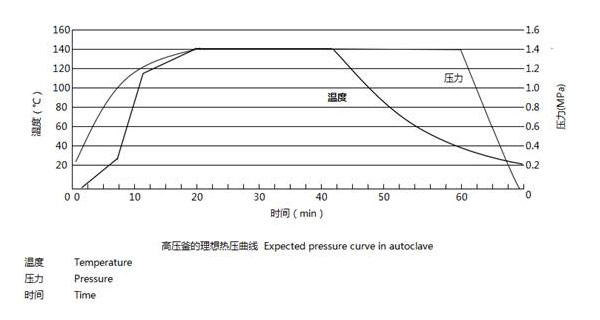

Laminated glass autoclaving determined viscous flow control and resolution of residual air in laminated glass, before autoclaving, should be properly controlled residual gas and deair between PVB interlayer and glass sheet, if temperature, pressure and time is appropriate, it can dissolve remaining air into PVB interlayer film and keep it in stage of heat-pressing processing in autoclave. In addition, must prevent heat conduction from like air or oil stain to infiltrate laminated glass when process in autoclave. Picture shows temperature, pressure and time ranges of common laminated glass in processing autoclave, for thicker laminated glass unit need longer dwell time and pressure.

Autoclave processing including three phases are heating, insulation and cooling, each step has its temperature and pressure.

1. Heating

Heating phases within its limitative time, temperature and pressure reached 135 ~ 140 ℃ and 11 ~ 14MPa. In order to produce high quality laminated glass, heat and pressure treatment must be synchronized in autoclave, if make pressure too fast, air or oil stain penetration may cause poor sealing of laminated glass. Contrary pressure is too slow (temperature increase exceeds pressure time), residual air will expand cause delamination or infiltration. Pressure rate is generally 0.06MPa / min, then heating rate is 5 ℃ / min.

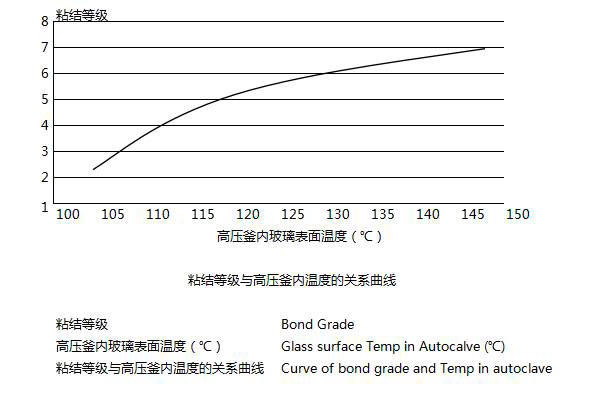

2. Insulation

Once temperature and pressure of autoclave reached requirements conditions, it must be maintained for a while, wait PVB interlayer changed as viscous material, Single laminated glass holding time is 10 ~ 25min, Insulation time depends on composition of laminated glass. Such as glass lites and thickness. For example like bulletproof glass structure 5G + 1.52PVB + 12G + 1.52PVB + 5G, the total thickness is 25.04mm, in order to reach temperature equilibrium and viscous flow that need long time; if short, PVB film has low temperature that can not bond with glass as well, it will lead to delamination, poor light transmission and other defects, Picture shows Influence of equilibrium temperature for adhesion in laminated glass.

3. Cooling

Before cooling, firstly should reduce temperature and pressure to predetermined value, main factor of cooling time controlling is cooling capacity and laminated glass quantities in autoclave, Normally cooling time is 25 ~ 35min, decompression until temperature must be reduced below 54 ℃ in autoclave , will certainly be appeared air bubbles in laminated glass.

The above complete cycle for each step, time around 55 ~ 80min. Time depends on equipment and thickness of laminated glass, If autoclave pressure time more than recommended time (Correct Autoclave operation), Please check thermal conductivity of the autoclave is impeded, or equipment heating and cooling system is defected, it need to repair autoclave, read instruction to maintaining autoclave and laminating glass production line.

(1) Delamination means glass and PVB interlayer is disengaged that appeared after installation of laminated glass, Delamination type have many shapes as sun-like, photokinesis, finger-like, or edge delamination.

(2) Reasons of Delamination

(3) Solutions of Delamination

(1) Air or other volatile gases be existed in middle or edge or other places in laminated glass.

(2) Reasons of Air Bubbles

(3) Solutions of air bubbles

(1) phenomenon of bubble bags

Air bags were appeared on surface of laminated glass, big or small irregularly existed anywhere like center or edge of laminated glass, most time occurs just out of autoclave, sometimes can seen lines of PVB film.

(2) Reason of bubble bags

(3) Solution of bubble bags

(1) Phenomenon

It appears edge region of laminated glass, there is unbonded place between glass sheet and PVB interlayer. This phenomenon is almost similar with delamination, but it appeared when out autoclave, however delamination phenomenon is not exist just out of autoclave. Typical defects of airbroken see pictures.

(2) Reasons

(3) Solutions

(1) Phenomenon

It happens no PVB film in border region between two pieces of glass and PVB film when deairing in prepressing or after, and happens after high temperature and pressure treatment.

(2) Reasons

(3) Solutions

(1) Phenomenon: bond strength decline

(2) Reasons

(3) Solutions

(1) Phenomenon: Impact resistance decline

(2) Reasons

(3) Solutions

(1) Phenomenon: Boiling test fails

(2) Causes

(3) solutions

| PROBLEMS | CAUSE | SOLUTIONS |

|---|---|---|

| DELAMINATION | - Insufficient adhesion. | - Increasing of the fusing time of ArchitexTM - Check pre-laminate temperature |

| RIPPLE / WHITE CLOUDS | - A blockage in the convection air flow. - Excess temperature in the cycle. - An insertion that absorbs excess heat |

- Verify that there is no glass positioned or an obstacle that doesn’t allow the correct airflow. - Lower degrees the temperature cycle - Verify that the Furnace lamas have not moved or have closed causing inequalities chamber temperature - Use the guide to know exactly cane glass temperature |

| EDGE BUBBLES | - Excess of temperature during fusing - Inserted objects too thick - Less time of “desaireado” |

If a step curve is used: - Increase the stopping time - Reducing of the temperature If a Lineal curve direct to the fusion point is used: - Increase the time of the segment up to achieve the fusion point. |

| BUBBLES IN THE MIDDLE OF THE LITE | - Excess of pressure in the edges of the glass. | - Reduce the time in the fusion segment depending on the thickness of the glass and the number of layers. - Put small pieces of wood if a vacuum bag is used. |

| BEAD IN GLASS DROPS IN THE EDGES DROPS AROUND THE INSERTION |

- Lack of support in large parts. usually on the vertical system - Large empty spaces caused by excessive expansion. appear at the ends of the rolled piece - Bags of air that round the insertion itself, caused by the lack of EVA - Excess of vacuum time |

- Increase of the number of supports - Shorten the process - Stop using the pump segment in the segment fusion - Remove tape - Reduce the number of layers that are being used - Shorten the process - Stop using the pump segment in the segment fusion - Increase the number of layers of EVA |